[ Cause analysis of casting defects ]

"The microstructure reflects the truth."

Understanding the causes is essential for defect countermajors.

Material design provides appropriate material analysis.

Cause analysis of Casting and HPDC Defects.

The objective of casting defect analysis

In addressing casting defects, it is crucial to identify the causes of casting defects. If the cause analysis is inaccurate, the efforts put into countermeasures will be in vain. In the casting defect analysis provided by Material Design, we conduct the following based on your specific requirements.

- Optical microscopy observation

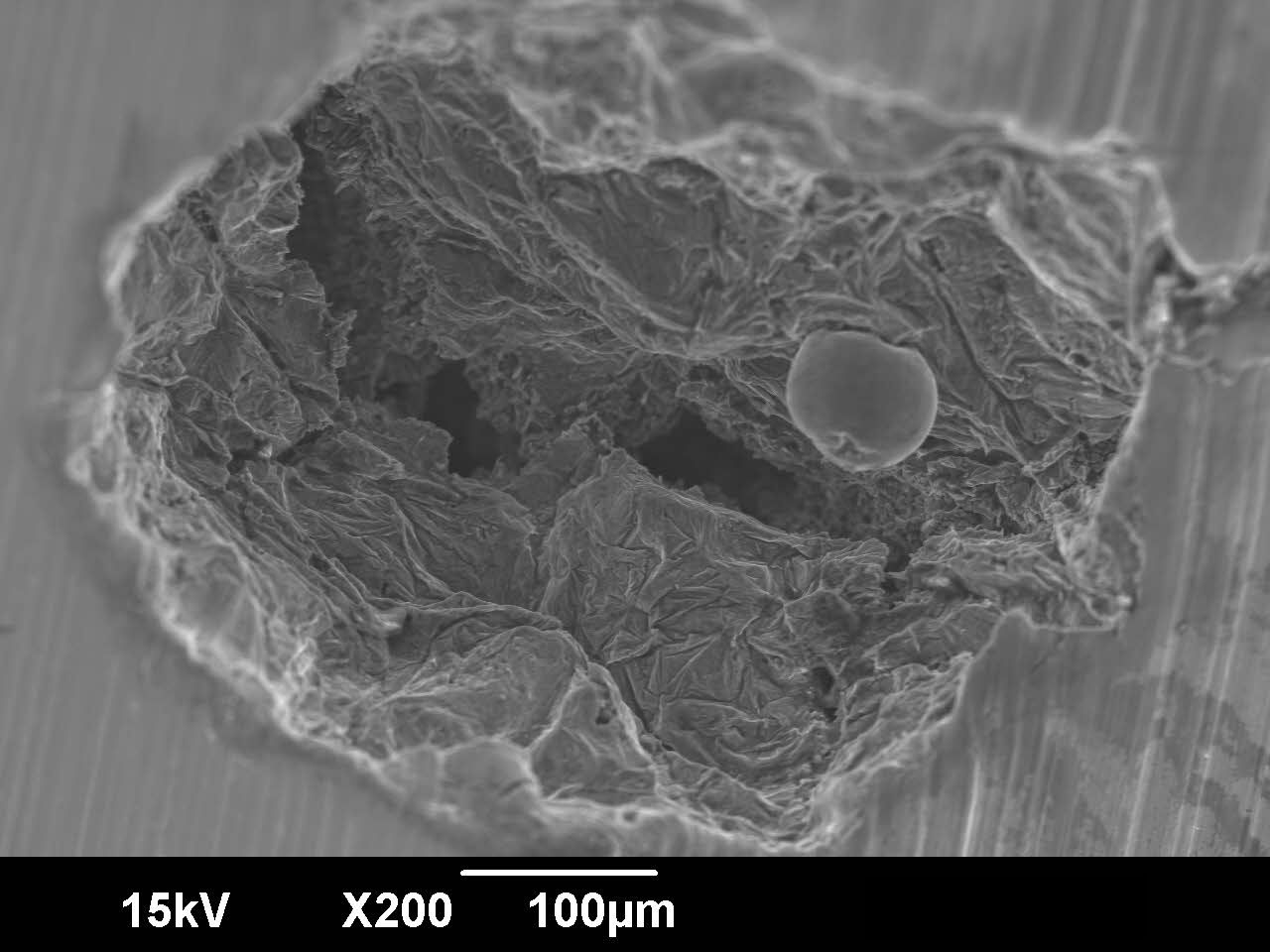

- SEM observation

- SEM-EDX analysis

- Microstructure determination

- Gas chromatography

- PoDFA

- CT

What can be understood through casting defect analysis

We offer analysis services for casting defects in HPDC and aluminum casting. Based on optical microscopy observation and SEM observation, we conduct analyses that are suitable for determining the causes of casting defects. For example, it is possible to analyze the following casting defects and processing defects:

- Shrinkage porosity

- Gas porosity

- flower mark

- Hard spots

Flow of Casting Defect Analysis

01

Ask

We will inquire about the specific details of the analysis you wish to have conducted.

02

Quotation

Based on the gathered requirements, we will provide you with a quotation.

03

Ordering

If you are satisfied with our quotation, please proceed with placing an order.

04

Investigation

We will conduct the investigation at our facility (typically involving destructive testing).

05

Report

We will report the analysis results through a written report or presentation.

Equipment usage and delivery deadlines will also be determined through discussions and consultations.

Advantages of Casting Defect Analysis

By comprehensively analyzing from macro to micro levels, the underlying causes of casting defects, which were previously unclear, can be understood. If you are interested in casting defect root cause analysis, please feel free to contact us for further inquiries.

Reference Prices for Defect Analysis

| Name | Analysis Type | Quantity | Price (incl. tax) |

|---|---|---|---|

| Start | Optical microscopy Microstructure observation Report |

1 | ¥121,000 |

| Standard | SEM observation Microstructure observation Report |

1 | ¥187,000 |

| Advanced | SEM observation Microstructure observation Elemental analysis Report |

1 | ¥220,000 |

The above prices are for reference purposes only. The scope of analysis may vary depending on the plan. Upon consultation, we will provide a quotation considering the feasibility of the analysis.

Material Design is a casting consultant. Please contact us for any issues related to your casting.

Contact Us