[ Services ]

Material Design captures the trends of the future casting industry.

Originating from the SDGs, electrification of automobiles,

adoption of secondary metals, and carbon neutrality of casting processes are urgent issues.

We work with our client companies to tackle these challenges and

contribute to their sustainable development.

What we can do

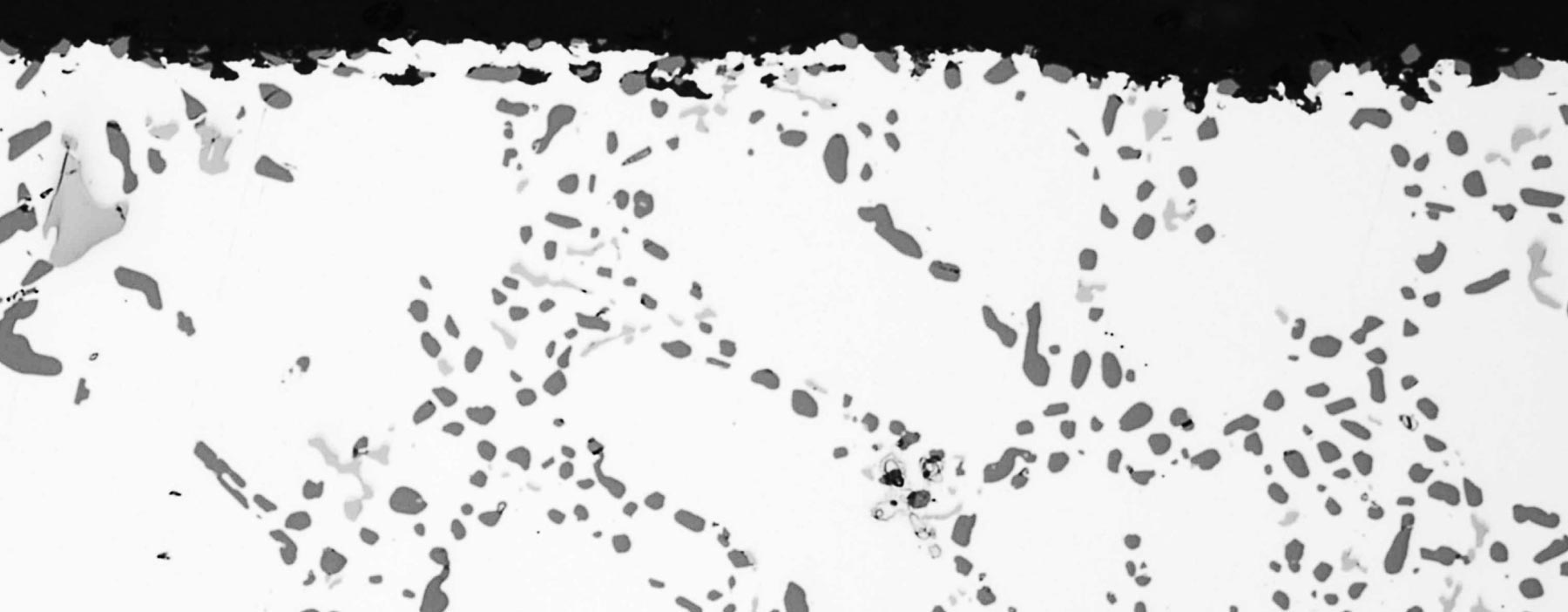

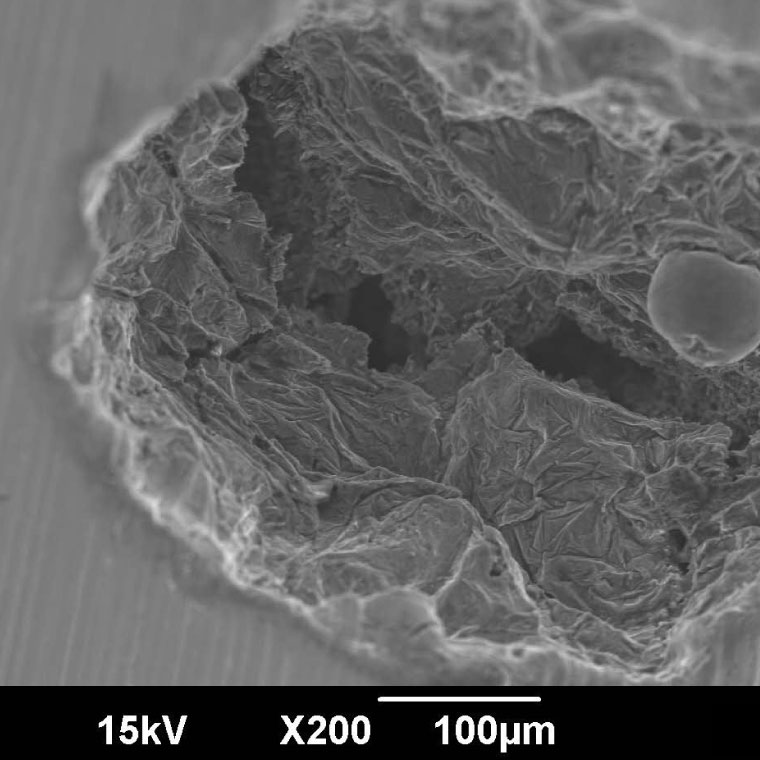

Cause analysis of casting defects

At Material Design, we provide analysis of casting defects for die-cast and aluminum castings. Based on optical microscope observation and SEM observation, we perform appropriate analysis for the cause of casting defects.

Casting Defects

- Shrinkage porosity

- Gas porosity

- Dimension defect

- Crack

- Hard spot

- other

Material types

- A383(JIS ADC12)

- A380(JIS ADC10)

- Silafont-36

- A356(JIS AC4CH)

- other

Benchmark survey

One of the services of Material Design is benchmark survey of aluminum castings. We estimate the material composition, casting method, heat treatment, joining, design concept, etc. of the castings. Benchmarking is important to know the trends of other companies, absorb new technologies, and know your own position. We can also produce samples of castings for basic data acquisition. By combining with mechanical property evaluation such as tensile test, the accuracy of benchmark evaluation can be improved.

Technical consulting

Material Design solves casting technology challenges. Casting is a metallurgical field with many unknowns. Industrial challenges require specialized knowledge in this area.

We can also support you globally, from web meetings to on-site investigations.

Issues we can handle

- Countermeasures for casting defects

- Efficiency improvement of casting plants

- Technology development

- Information gathering

- Support for Japanese manufacturers